The Diecast Model Car Factory: An Overview

The world of diecast model cars is a fascinating blend of art, engineering, and mass production. These miniature replicas, often prized by collectors and enthusiasts, are created in factories using intricate processes. Understanding the secrets behind these factories provides a deeper appreciation for the craftsmanship and precision involved in bringing these small-scale vehicles to life. From the initial concept to the final product, each stage plays a crucial role in the creation of a high-quality diecast model car. The following sections delve into the top 5 secrets of diecast model car factories, revealing the hidden details of their production.

Secret 1 Raw Materials & Production

The foundation of any great diecast model lies in its raw materials and the initial production steps. The selection and preparation of these materials directly impact the quality, durability, and detail of the finished product. Understanding the sourcing and handling of these materials is the first secret to unlocking the mysteries of diecast model car factories. This involves careful consideration of material properties, cost-effectiveness, and environmental impact, ensuring that the final model not only looks authentic but also meets stringent quality standards. It is a critical stage in determining the overall quality of the final product and its ability to withstand the test of time.

Types of Materials Used

The primary material used in diecast model car production is a zinc alloy, often combined with other metals like aluminum and copper. This alloy provides the necessary strength and weight for the model. Plastic components are also crucial, used for items like interiors, tires, and other details. High-quality plastics are selected for their durability, appearance, and ability to hold detailed features. The choice of materials is not just about aesthetics; it also involves considering how the components will interact with the die-casting process, painting, and assembly. Ensuring that the materials are compatible and capable of producing detailed and durable models is essential for the factory.

The Production Process

The raw materials undergo several crucial steps before taking shape as a diecast model car. The process starts with melting the metal alloy and preparing the plastic components. The metal alloy must be heated to a specific temperature to ensure optimal flow during the casting process. Plastic parts are typically created through injection molding, where molten plastic is injected into molds. These initial stages are crucial for ensuring the accuracy and quality of each component. The consistency in these early steps directly affects the level of detail and precision in the finished product. It also involves rigorous quality control measures to minimize defects and maintain efficiency.

Secret 2 The Die-Casting Process

The die-casting process is the heart of diecast model car production, a complex method that transforms molten metal into intricate car bodies. This process is what truly sets diecast models apart from other types of toys. Understanding the intricacies of die-casting reveals the skill and technology that goes into each model. The precision involved ensures that every curve, edge, and detail is accurately replicated. It’s a blend of art and science, where the engineers and technicians must master the process for producing a high-quality product consistently. The choice of casting materials and the technology employed are both important to the final product.

Metal Casting

Metal casting in a diecast model car factory involves injecting molten metal alloy into steel molds under high pressure. The molten metal quickly fills the mold, taking the shape of the car body and other metal components. The process requires careful control of temperature, pressure, and cooling to ensure the metal solidifies correctly and that all details are captured. The precision of the casting process is critical, as it determines the overall shape, size, and detail of the car. It’s a highly automated and efficient method, but it also requires constant monitoring and quality checks to prevent imperfections and ensure consistency. This is often the start of a model’s journey from raw materials to a finished replica.

Mold Creation

The creation of molds is a critical step in the die-casting process, as the quality of the molds determines the accuracy and detail of the model cars. Molds are typically made from high-strength steel, capable of withstanding high pressure and temperatures. The molds are created with extreme precision, often using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. Each mold is composed of multiple parts, carefully designed to create every aspect of the car’s body and other components. The molds are constantly maintained and inspected to ensure they produce consistent and accurate parts, allowing factories to reproduce models with remarkable accuracy, making the final product as close to the original as possible.

Secret 3 Painting and Detailing

Once the die-cast metal components are produced, the next crucial stage is painting and detailing. This is where the model car starts to truly resemble its real-life counterpart. The painting process involves multiple layers and meticulous attention to color accuracy. Detailing includes applying decals, adding interior features, and other finishing touches that bring the model to life. The skills of the painters and detailers are essential in creating a high-quality model. The quality of the paint, the application techniques, and the precision of the detailing all contribute to the final appearance of the model. Every detail matters at this stage in production.

Paint Application Techniques

Diecast model car factories use advanced painting techniques to achieve a flawless finish. These techniques include electrostatic painting, which ensures an even coat of paint, and multiple layers of paint to achieve the desired color and durability. The paint is carefully chosen to match the original car’s color precisely, with special attention given to the paint’s gloss level and finish. Some models also use a clear coat to protect the paint and add a glossy sheen. The application process is carried out in a controlled environment, minimizing dust and ensuring an even coating. It’s a delicate process, requiring skilled technicians and advanced equipment to achieve the best results.

Detailing the Model Car

Detailing is the art of bringing a diecast model car to life. It includes adding decals, which may include logos, stripes, and other markings, as well as the application of interior details such as seats, dashboards, and steering wheels. The detailers use specialized tools and techniques to apply these features with precision. Some models include photo-etched parts, which are small, detailed metal components used for items like grilles and emblems. Detailing requires a steady hand and keen eye to ensure accuracy and quality. The addition of tiny details can make a huge difference in the overall look and feel of the model, transforming it from a simple replica into a work of art.

Secret 4 Assembly and Quality Control

The assembly and quality control stages are crucial in determining the final quality of a diecast model car. This is where all the individual components are brought together to form the finished product. Quality control ensures that the model meets the required standards for accuracy, detailing, and overall appearance. Rigorous checks are carried out at various stages of assembly. The combination of skilled workers and thorough inspection processes is the key to producing a high-quality product. It’s a process of continuous evaluation, with a focus on minimizing defects and maximizing customer satisfaction. This is the final stretch before the model car can be enjoyed by collectors.

Assembly Steps

Assembly involves putting all the components of the model car together. This includes attaching the body to the chassis, adding wheels, inserting interior details, and attaching any external accessories. Skilled workers use specialized tools and techniques to ensure a precise fit and finish. Some models have complex assembly processes with dozens of individual parts. Each step must be executed with care and attention to detail to prevent damage or misalignment. The assembly process is carefully choreographed to maintain efficiency and quality, with multiple quality checks throughout.

Quality Assurance Checks

Quality assurance is a vital step in the diecast model car production. Trained inspectors meticulously check each model car for defects such as paint imperfections, misaligned parts, and missing details. These checks may involve visual inspections, dimensional measurements, and functional tests. Any defects are addressed through rework or rejection. The goal is to ensure that every model car meets the high standards set by the manufacturer. Random samples are also subjected to more rigorous testing to ensure consistency and durability. This commitment to quality helps maintain the reputation of the brand and ensures customer satisfaction. The factory strives to create model cars that are both beautiful and durable.

Secret 5 Packaging and Distribution

The final stage in diecast model car production is packaging and distribution. This is how the finished product reaches the collectors and enthusiasts who will treasure them. The packaging process involves carefully securing the model car in a protective box, often with a display stand. Distribution channels include retailers, online stores, and direct sales. The attention to detail at this stage is also important, as the packaging protects the model during transit and provides valuable information to the consumer. The goal is to get the model car to its destination in perfect condition, ready to be admired and enjoyed.

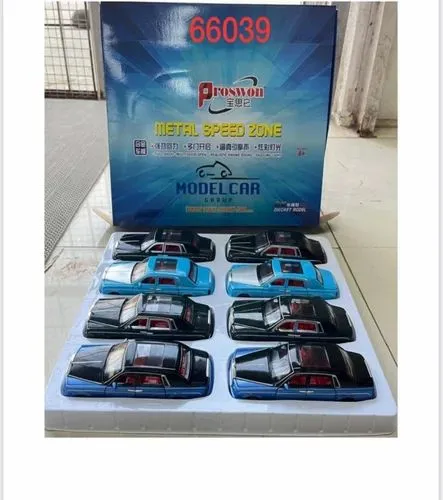

Packaging Process

The packaging process involves carefully securing the diecast model car in a protective box. This usually includes a clear plastic display case to showcase the model and prevent scratches or damage. The model car is often secured to a base or stand inside the box. The packaging is designed to protect the model during transit and storage. The packaging also often includes information about the model car, such as its make, model, scale, and a brief history. High-quality packaging enhances the perceived value of the model and appeals to collectors. The packaging also often features attractive graphics and branding, further enhancing the overall appeal.

Distribution Channels

Diecast model cars are distributed through various channels, including retail stores, online marketplaces, and specialized hobby shops. Retail stores provide a physical space for customers to browse and purchase models. Online marketplaces offer a vast selection and convenient shopping experiences. Specialty hobby shops often cater to collectors and enthusiasts, offering rare and limited-edition models. The distribution process involves a complex network of suppliers, distributors, and retailers. The goal is to ensure that the model cars are available to customers worldwide. Effective distribution ensures models reach the right customers at the right time.