The Essence of Diecast Construction Models

Diecast construction models offer a unique blend of artistry, engineering, and nostalgia, appealing to collectors, hobbyists, and enthusiasts alike. These miniature replicas of real-world construction vehicles are meticulously crafted using a process known as die-casting, where molten metal is injected into molds to create highly detailed and durable models. Understanding the construction features is key to appreciating the craftsmanship and value of these detailed miniatures. From the initial design to the final packaging, every aspect contributes to the model’s overall quality and appeal, making it a fascinating subject for anyone interested in the world of miniature construction equipment and the art of model making. This article will delve into the top 7 construction features that define the excellence of diecast construction models, helping collectors and enthusiasts make informed decisions and appreciate the intricacies of these miniature marvels.

Weight and Durability

One of the most significant advantages of diecast construction models is their weight and durability. The use of metal alloys, primarily zinc, allows these models to feel substantial in hand, enhancing the tactile experience and providing a sense of quality. This inherent weight also contributes to the model’s stability, preventing it from easily tipping over or being damaged. The robust construction means that diecast models can withstand a certain amount of handling and play, making them suitable for both display and occasional use. The weight and durability are not merely aesthetic factors but also indicative of the quality of materials and the precision of the manufacturing process, making them a lasting addition to any collection.

Metal Composition

The metal composition of diecast models is crucial to their overall quality and longevity. Zinc alloys are the most common choice, owing to their excellent casting properties, ability to capture fine details, and relatively low melting point. This allows manufacturers to create intricate designs with precision. Other metals, such as aluminum and steel, may also be incorporated, particularly for structural components or specific features. The blend of metals used often determines the model’s weight, durability, and even its resistance to corrosion. The choice of metal composition is thus a critical element in the construction of diecast models, influencing both their aesthetic appeal and their structural integrity. Understanding these metal choices helps in assessing the model’s overall value and its potential lifespan.

Zinc Alloy vs. Other Metals

Zinc alloys are popular in diecast models because they offer a good balance of cost-effectiveness, castability, and detail reproduction. They can be cast into intricate shapes, allowing for the creation of complex models with fine details. However, zinc alloys are prone to “zinc pest,” a form of corrosion that can occur over time under certain environmental conditions. Other metals, like aluminum, offer better corrosion resistance but may be more expensive or not able to capture fine details. Steel is extremely durable but often used for structural components rather than the entire model because it’s harder to cast. The selection of metal ultimately involves a trade-off between cost, detail, and durability, with manufacturers often using a combination of materials to achieve the best results, focusing on the primary metal and supplementing it with others for specific parts or functions.

Authentic Detailing

Authentic detailing is a hallmark of high-quality diecast construction models. This involves replicating the appearance of real-world construction vehicles with meticulous precision, from the overall design and shape to the smallest features such as rivets, grilles, and warning labels. The detail extends to the interior of the vehicles, with accurately rendered seats, dashboards, and control panels. Advanced manufacturing techniques and precise tooling are necessary to achieve this level of realism. The better the detailing, the more valuable and sought-after the model is likely to be among collectors. Detail also includes the realistic use of paint and markings, including weathering effects to simulate wear and tear. The ultimate goal is to provide a miniature replica that is as close to the real vehicle as possible, appealing to both the eye and the collector’s desire for accuracy.

Accurate Scale

Accurate scaling is essential for the authenticity of diecast construction models. Models are created in specific scales, such as 1:50, 1:25, or 1:87 (HO scale), meaning that every dimension of the miniature is proportionally reduced from the real-world vehicle. Precise scaling ensures that the model accurately represents the vehicle’s size and proportions. Maintaining this accuracy throughout the entire model, from the overall dimensions to the size of individual components, is vital for the model’s realism. This level of precision is crucial for collectors who often display their models together, where variations in scale would be immediately apparent. Proper scaling is also a key factor in the model’s value, as it reflects the manufacturer’s commitment to accuracy and detail. Incorrect scaling can severely detract from the model’s authenticity and desirability.

Popular Scales

Several scales are commonly used in the diecast construction model industry, each catering to different preferences and display needs. The 1:50 scale is particularly popular for its balance of detail and size, making it suitable for displaying individual models or creating dioramas. The 1:87 (HO scale) is another popular choice, especially for railway enthusiasts who incorporate construction vehicles into their layouts. This scale allows for a large number of models to be displayed in a relatively small space. Larger scales, such as 1:25, offer even greater detail but require more display space. The choice of scale often depends on the collector’s personal preferences, available space, and the types of models they wish to collect. The availability of models in a particular scale is also a factor, with some scales offering a wider selection than others.

Functioning Components

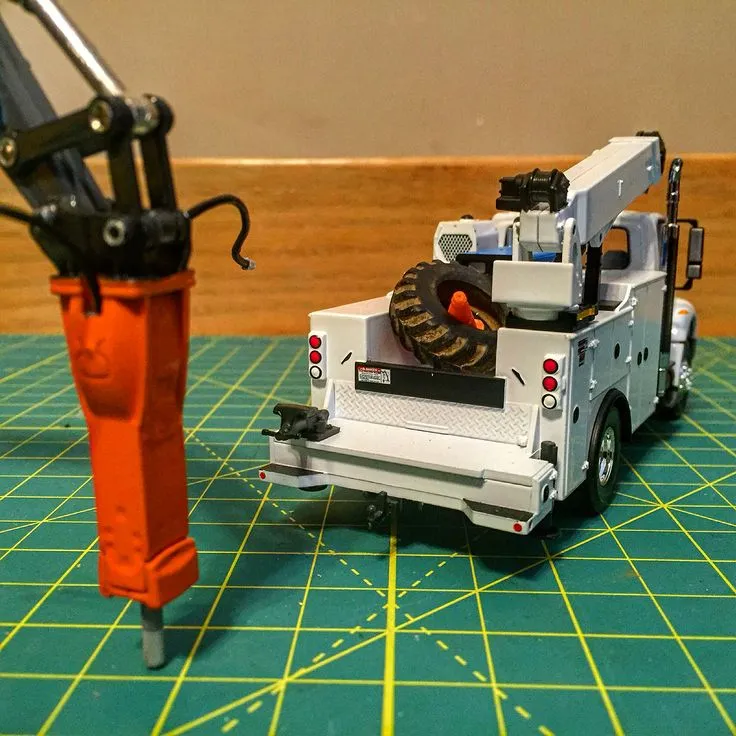

Many high-quality diecast construction models feature functioning components that add to their realism and play value. These can include articulating arms and buckets on excavators, adjustable blades on bulldozers, and functioning steering mechanisms. The inclusion of these features significantly enhances the model’s authenticity, allowing enthusiasts to interact with the model in a way that mimics the operation of a real construction vehicle. The precision engineering required to create these functioning parts demonstrates the high level of craftsmanship involved. Models with functioning components often command a higher price and are highly sought-after by collectors who appreciate the added level of detail and realism. These features elevate the model from a static display piece to an engaging miniature replica.

Moving Parts in Diecast Models

Moving parts are a key aspect of diecast construction models, adding to their realism and playability. These components, such as articulating arms, tilting beds, and rotating turrets, are designed to function similarly to their real-world counterparts. The design and construction of these moving parts require precision engineering to ensure smooth operation and durability. Hinges, pins, and joints are strategically placed to allow for a wide range of movement. Some models even feature hydraulic systems that allow for more complex movement and greater realism. These moving parts not only enhance the model’s visual appeal but also provide a more interactive experience, allowing collectors to pose and position their models in various ways, enhancing their display.

Hydraulic Systems Replication

The replication of hydraulic systems in diecast construction models is a testament to the manufacturer’s commitment to detail and realism. While not always functional in a practical sense, these models often include detailed representations of hydraulic cylinders, hoses, and other components found in real construction vehicles. These components are carefully positioned and often made from materials that closely resemble the originals, enhancing the overall look. Some advanced models may even incorporate functional hydraulic systems, allowing for realistic movement of arms, buckets, and other parts. This level of detail is highly prized by collectors, as it showcases the complexity and engineering of the real construction equipment. These models highlight the craftsmanship and dedication to accuracy.

Paint and Finish Quality

The paint and finish quality of a diecast construction model is a crucial aspect of its visual appeal and overall value. High-quality models feature smooth, even paint applications that accurately reflect the colors and markings of the real-world vehicles. The paint should be durable and resistant to chipping or fading over time. The finish may vary, from a glossy sheen to a more matte appearance, depending on the specific vehicle being replicated. Attention to detail is vital; this includes applying precise decals and markings that match the original construction equipment. The quality of the paint and finish directly impacts the model’s realism and its appeal to collectors. A well-executed paint job can elevate a model, making it look authentic and enhance its value. The absence of imperfections contributes significantly to the overall visual impression.

Paint Application Techniques

Various paint application techniques are used in the production of diecast construction models, each contributing to the final appearance and detail. Pad printing is commonly used for applying logos, markings, and fine details, providing sharp and accurate images. Spray painting ensures an even coat of paint on the model’s surfaces, which is vital for consistency. The layering of paint is used to achieve specific effects. Clear coats may be applied to protect the paint and enhance its shine. Skilled artisans carefully control these techniques, ensuring the paint adheres correctly to the metal and replicates the look of the actual vehicles. These methods work together to ensure that each model is of the highest quality, resulting in a realistic and durable finish.

Weathering and Aging Effects

Weathering and aging effects are often applied to diecast construction models to enhance their realism and create a more authentic representation of real-world construction vehicles. These techniques involve simulating the wear and tear that vehicles experience in their working lives. This includes adding rust, dirt, scratches, and fading to the paint, providing a sense of realism. Weathering can be done using various methods, such as washes, dry brushing, and airbrushing. These techniques require skill and artistry to create a realistic appearance. The application of weathering effects adds depth and character to the models, making them look as if they have been working on construction sites. This process increases a model’s realism, turning it into a more appealing and sought-after item for collectors who appreciate authenticity.

Packaging and Presentation

The packaging and presentation of diecast construction models play an important role in their appeal and perceived value. High-quality models are often presented in attractive boxes, which protect the model during shipping and storage. The packaging may include detailed information about the model, such as its scale, manufacturer, and specific features. Some models also include certificates of authenticity, which further enhance their value. The packaging is often designed to reflect the model’s quality and the brand’s image. Presentation can be key for collectors, making the unboxing experience part of the collecting experience. The right packaging can make the model much more attractive to buyers.

Protective Packaging Materials

Protective packaging materials are essential for ensuring that diecast construction models arrive in perfect condition. These materials are designed to cushion the model during shipping and prevent damage from impact, vibration, and other potential hazards. Common protective packaging materials include foam inserts, bubble wrap, and custom-molded trays that hold the model securely in place. High-quality packaging materials also help to prevent scratches and other cosmetic damage. These materials are critical in preserving the value and condition of the model. The best manufacturers use packaging that is both protective and aesthetically pleasing, contributing to the overall presentation of the model and enhance the collector’s experience from the moment the package arrives.

Collector’s Editions

Collector’s editions of diecast construction models offer unique features and enhancements that set them apart from standard releases. These editions may include limited production runs, special paint schemes, exclusive detailing, and numbered certificates of authenticity. Collector’s editions often feature premium packaging and display cases, enhancing their value and collectibility. Some collector’s editions may also include additional accessories, such as tools, figures, or diorama elements. Collectors are often willing to pay a premium for these special editions, as they represent a unique opportunity to own a rare and highly sought-after model. The scarcity, unique features, and superior presentation of collector’s editions make them especially valuable in the world of model collecting.

Brand Reputation and Licensing

Brand reputation and licensing agreements are critical factors in the diecast construction model industry, influencing the quality, authenticity, and value of the models. Well-established brands with a strong reputation for quality, detail, and innovation are highly respected by collectors. These brands often have a long history of producing high-quality models and are trusted by enthusiasts worldwide. Licensing agreements with construction equipment manufacturers are essential for creating authentic replicas of real-world vehicles. These agreements grant the model makers the right to use the manufacturer’s trademarks, designs, and technical specifications, ensuring accuracy and realism. The combination of a strong brand reputation and valid licensing agreements is key to producing high-quality diecast models that are highly sought-after by collectors and enthusiasts.

Licensing Agreements

Licensing agreements play a crucial role in the creation of authentic diecast construction models. These agreements grant model manufacturers the permission to replicate the designs, trademarks, and specifications of real construction equipment. Without proper licensing, model makers are unable to create accurate replicas of these vehicles. Licensing agreements ensure that the models are faithful representations of the original vehicles. The licensing process involves negotiating terms with construction equipment manufacturers, including royalty fees, design approvals, and production limitations. These agreements protect intellectual property rights and ensure that the models meet certain quality standards. The presence of licensing agreements indicates the model’s authenticity and its official connection to the brand, increasing its appeal and value among collectors. These agreements are the foundation upon which authentic diecast construction models are built.

Manufacturer’s Reputation

The manufacturer’s reputation is a significant factor in the diecast model industry, impacting the perceived quality, value, and collectibility of the models. Manufacturers who consistently produce high-quality models with exceptional detailing, accuracy, and durability earn a strong reputation among collectors. These companies are known for their commitment to craftsmanship, their use of premium materials, and their attention to detail. A reputable manufacturer will often have a long history of producing models and a proven track record of customer satisfaction. Collectors often place a higher value on models from reputable manufacturers, as they can be confident in the quality and authenticity of the product. The manufacturer’s reputation also affects the resale value of the models, with well-regarded brands often commanding higher prices in the secondary market.

In conclusion, the top 7 construction features of diecast models – including weight and durability, authentic detailing, accurate scale, functioning components, paint and finish quality, packaging and presentation, and brand reputation and licensing – are all essential for creating high-quality, collectible miniatures. Understanding these features enables collectors to appreciate the craftsmanship, value, and intricate details that make these models so appealing. Whether you are a seasoned collector or just starting out, focusing on these aspects will guide you toward finding models that bring you joy and stand the test of time. The combination of these features determines the model’s authenticity, playability, and overall appeal. These are the key things to look for when buying construction models.