What is Norev Diecast Quality

Norev is a well-regarded name in the diecast model car world, and their reputation is built upon a commitment to quality. When we talk about Norev diecast quality, we’re referring to the overall excellence of their model cars, from the materials used to the final presentation. This encompasses a range of factors, including the accuracy of the model’s design, the quality of the paint finish, the level of detail, and the durability of the construction. High-quality Norev diecast models are sought after by collectors and enthusiasts who appreciate the craftsmanship and the realistic representation of the original vehicles. These models are not just toys; they are miniature works of art, often displayed and treasured for their aesthetic and historical value. The diecast process itself, involving the injection of molten metal into molds, is a complex art that Norev has mastered, producing detailed and accurate miniature replicas. Understanding the features that contribute to this quality is essential for anyone considering adding a Norev model to their collection.

Attention to Detail

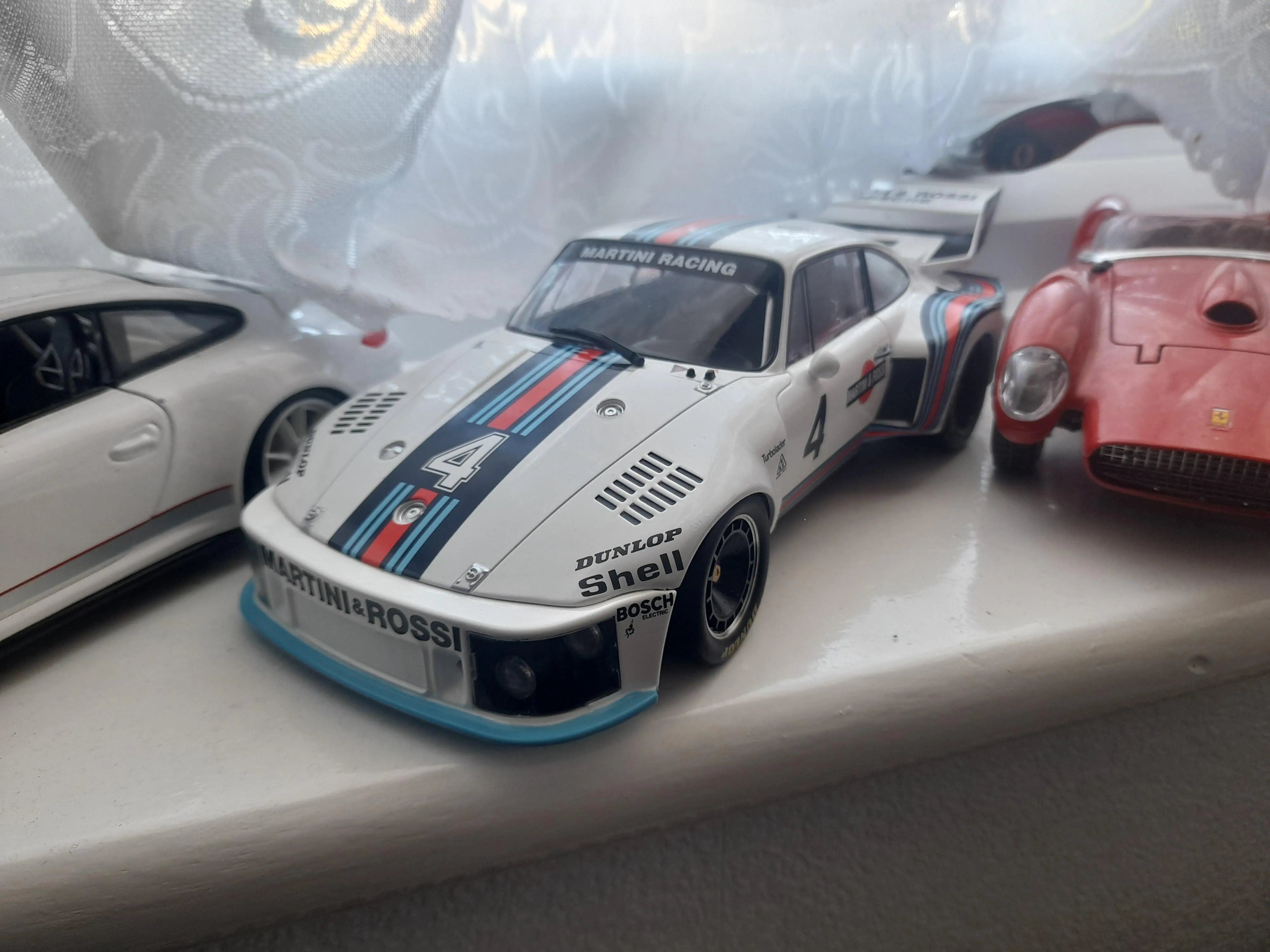

One of the most striking aspects of Norev diecast quality is the meticulous attention to detail. This goes beyond simply replicating the shape of a car; it extends to the smallest features, such as the texture of the seats, the design of the dashboard, and the intricate workings of the engine bay. Norev models often include separate components for items like door handles, windshield wipers, and even tiny emblems, enhancing the realism. The precision with which these details are crafted and assembled is a testament to Norev’s dedication to accuracy. The use of high-resolution photography and detailed blueprints during the design process enables Norev to capture the essence of the original vehicle. The attention to detail elevates the model from a simple toy to a highly accurate miniature representation, appealing to collectors who value authenticity and realism. This commitment to detail is a hallmark of Norev’s quality and a key reason why their models are so highly regarded.

Paint Finish and Application

The paint finish on a Norev diecast model is another critical indicator of its overall quality. The paint must be applied smoothly, evenly, and with a high degree of accuracy to match the original car’s color and finish. Norev employs advanced painting techniques to achieve a flawless appearance, minimizing imperfections like runs, bubbles, or inconsistencies in color. The paint also needs to be durable, resistant to chipping, fading, and damage over time, preserving the model’s aesthetic appeal. Norev often uses multiple layers of paint, along with clear coats, to create a deep, lustrous finish that enhances the model’s visual impact. The correct application of the paint is not merely a cosmetic consideration; it contributes significantly to the overall realism of the model. The paint job can make or break the overall look of a model car, and Norev diecast quality shines through in the precise and flawless finish that collectors admire. The choice of color and the correct finish are all crucial in making the model car look as close to the real car as possible.

Material Selection

The quality of materials used in a Norev diecast model directly affects its durability, appearance, and overall value. Norev typically utilizes high-quality diecast metal alloys for the main body and chassis, providing a solid and weighty feel that distinguishes a premium model. The metal is carefully chosen for its ability to capture fine details during the molding process and for its resistance to corrosion. In addition to the metal, Norev uses various other materials such as high-quality plastics for interior components, clear acrylic for windows, and rubber or similar materials for tires. These materials are selected for their durability, accuracy, and ability to replicate the look and feel of the original vehicle. The quality of these materials contributes to the model’s longevity, ensuring that it can withstand handling and display over time. The choice of material greatly affects the model’s overall appearance, making it a key consideration in ensuring that the Norev diecast quality is upheld. The feel and finish of the materials used adds to the model’s collectability and desirability.

Assembly and Construction Quality

The assembly and construction of a Norev diecast model play a crucial role in its overall quality and longevity. The various components of the model, from the body panels to the interior details, must fit together precisely, without gaps or misalignments. Norev employs skilled craftsmanship and rigorous quality control procedures to ensure that each model is assembled to the highest standards. This includes carefully aligning parts, securing them with precision, and ensuring that moving parts, such as doors and wheels, function smoothly. The level of detail in the assembly process, such as the use of tiny screws and fasteners, reflects the commitment to a quality build. A well-constructed model is more durable and less prone to damage, preserving its value and appeal for years to come. The tight tolerances and precise fitting of parts are critical for achieving the overall look of the model. The quality of the construction directly impacts the model’s ability to withstand the test of time and handling, making it an essential aspect of Norev diecast quality.

Accuracy of Model Design

The accuracy of the model’s design is a cornerstone of Norev diecast quality. This involves the precise replication of the original vehicle’s dimensions, proportions, and features. Norev goes to great lengths to ensure that their models accurately represent the cars they are based on, using detailed blueprints, photographs, and sometimes even access to the actual vehicles. This meticulous approach includes replicating subtle details, such as the shape of the headlights, the design of the wheels, and the contours of the body panels. The accuracy of the design is what separates a high-quality model from a generic toy. Collectors and enthusiasts value models that are true to life, and Norev’s commitment to accuracy is a key reason why their models are so highly sought after. The design also accounts for the scale of the model, ensuring that all features are proportionate to the original vehicle. The more accurately the design, the better the model will look. Attention to design details contributes to a realistic and impressive model that is instantly recognizable.

Conclusion

Norev diecast quality is a combination of meticulous attention to detail, high-quality materials, precise paint application, and accurate design. These factors contribute to the overall excellence of their model cars, making them highly valued by collectors and enthusiasts. From the intricate interiors to the flawless paint finishes, every aspect of a Norev model reflects a commitment to producing miniature works of art. Understanding these key features helps appreciate the craftsmanship and value behind a Norev diecast model. Investing in a Norev model is investing in a piece of automotive history, perfectly recreated in miniature form. Choosing a Norev diecast model means choosing quality, accuracy, and a lasting tribute to the beauty of the original vehicles. The Norev brand has become synonymous with quality and it is a result of their commitment to provide the best model cars possible.